PTI Engineered Plastics

Prototype & Low-to-Mid Volume Plastic Injection Molding

PTI delivers precision plastic injection molding for low to medium volume production runs. With state-of-the-art equipment and decades of experience, they transform your designs into high-quality plastic components.

About

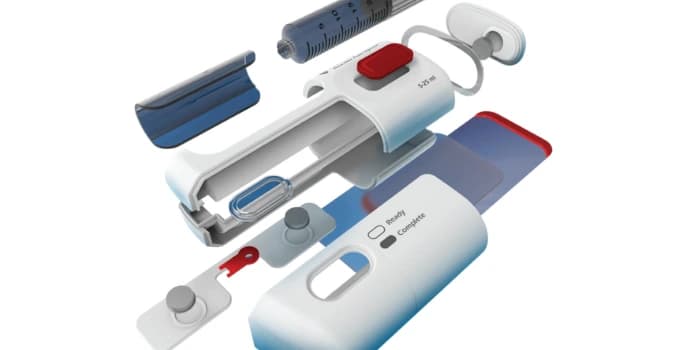

PTI Engineered Plastics, located in Macomb, Michigan, is a leading full-service injection molding and tooling company specializing in custom plastic components for the medical, defense, automotive, and industrial markets. With in-house design, engineering, and tool-building capabilities, PTI provides complete product development support from prototype through production. The company offers precision injection molding—including cleanroom manufacturing, insert molding, and rapid prototyping—along with advanced assembly, decorating, and finishing services. As an ISO 13485 and ISO 9001 certified, FDA-registered facility, PTI is recognized for its focus on quality, innovation, and speed-to-market for complex, highly regulated applications.

Key Specialties

Certifications & Compliance

ISO 9001

Quality Management System

Issued by: ISO

ISO 13485:2016

Medical Device Quality Management

Issued by: ISO

AC 8160

MedAccred

Issued by: PRI

Equipment & Capabilities

60 Injection Molding Machines

Plastic Injection Molding

Capabilities

- • High Temperature Molding

- • Insert Molding

- • Over Molding

- • ISO Class 8 Cleanroom for Molding & Assembly

Specifications

- Tonnage Range

- 35-300 tons

- Shot Size

- 0.09 to 25.56 oz.

Prototype Injection Molding

Rapid Prototyping

Capabilities

- • Fast turnaround prototypes

- • Design validation

- • Functional testing

- • Small batch production

Specifications

- Time to Market

- Average 3-5 weeks

- Part Runs

- Prototype to Large Volume

Design for Manufacturing

Engineering Services

Capabilities

- • Design optimization

- • Cost reduction analysis

- • Material selection

- • Manufacturability review

- • DFM consultation

Specifications

- Service Type

- Engineering Support

- Expertise

- Injection Molding & Tooling

- Availability

- Full-time support